Double Heads Tube Bending Machine

Chosen for its unparalleled productivity, the double heads tube benders SW series is able to make 2 bends X Multiple tubes simultaneously.- Direct supply from the manufacturer

- Order phone:+86-13812981723

- E-mail:liye@liyemachine.com

Detail

• Standard with 90° head rotation for Tube Bending

• Stationary clamps to maintain the tube in position before bending

• Arc movement of the bending heads allows high production rates

• Low setup times with quick-change tooling design and readout for length and angle settings

• Production speed: 3.8 seconds (25.4 mm X 2t X 90°, 2 tubes at one time)(Tube Diameter 12mm,3 tubes at one time)

• PLC control for easy operation and maintenance

• Full-cycle bending + half-cycle bending

Individual bending angle setting for each bending head

Readouts for the settings of the bending angles and straight distance between bends

Can process 2 bends and 2 tubes to X Multiple tubes (depands on tube diameter)at the same time

Center distance between bends from 110 mm to 1,800 mm

Double heads pipe bender can be divided into standard type (SW38) and rotary type (SW38A) according to structure of the base. The head of the rotary type bender (SW38A) can adjust the angle of elbow freely, but it shall consider the material feed problem.

Description

| Brand Name: |

LYM |

| Model Number: |

SW25B/SW38/SW38A/SW50/SW50A |

| Type |

NC CONTROL SEMI-AUTOMATIC |

| Certification: |

CE/SGS/TUV/ISO |

| Place of Origin: |

China |

| Application |

Pipes or solid bars,various materials such as steel, stainless, aluminum and copper |

| Packaging Details |

Packed in stretch film firstly,and then reinforced with plywood for outer packing |

DOUBLE HEADS PIPE BENDER MAIN TECHNICAL SPECIFICATION (NC CONTOL SERIES)

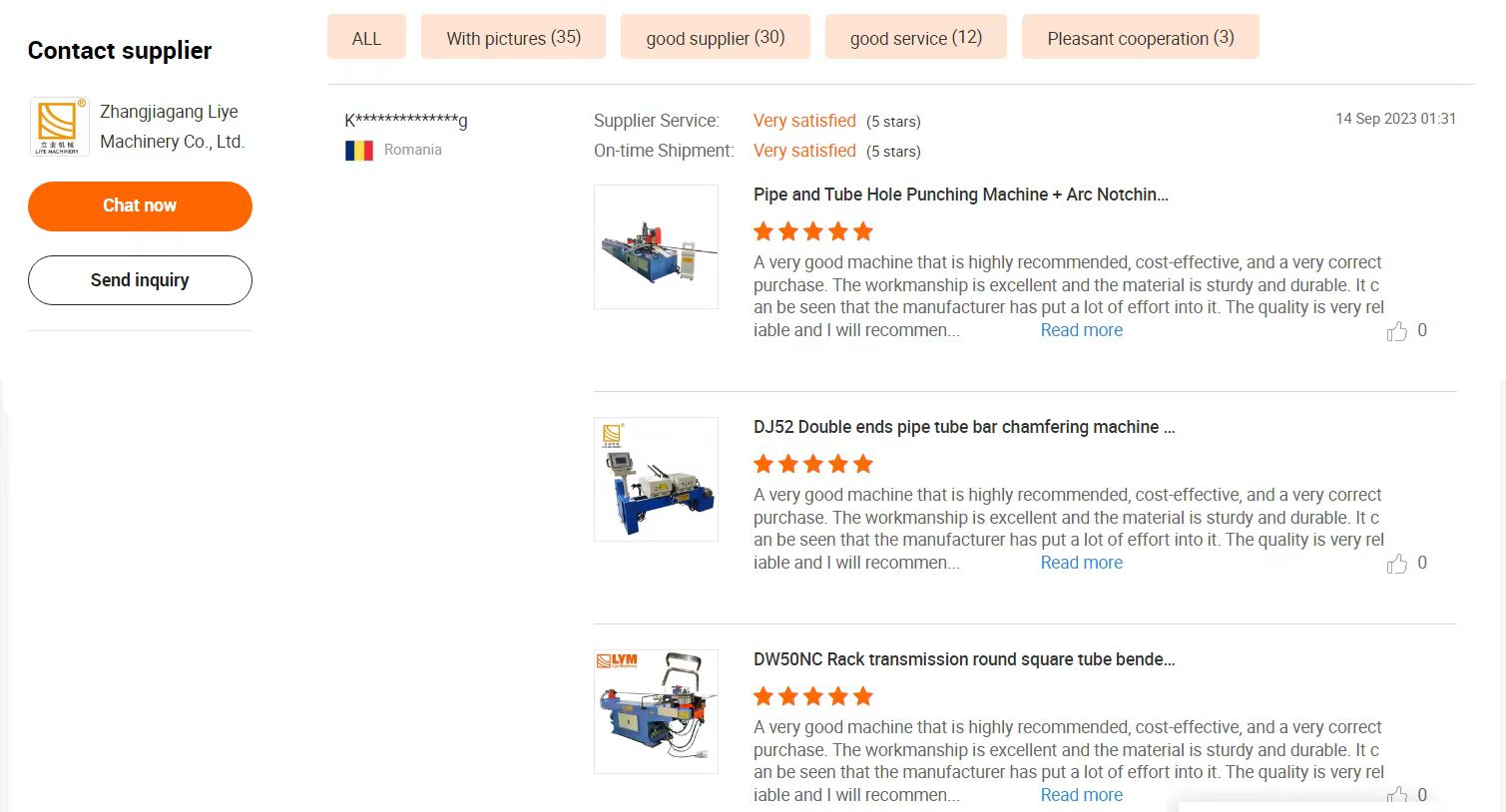

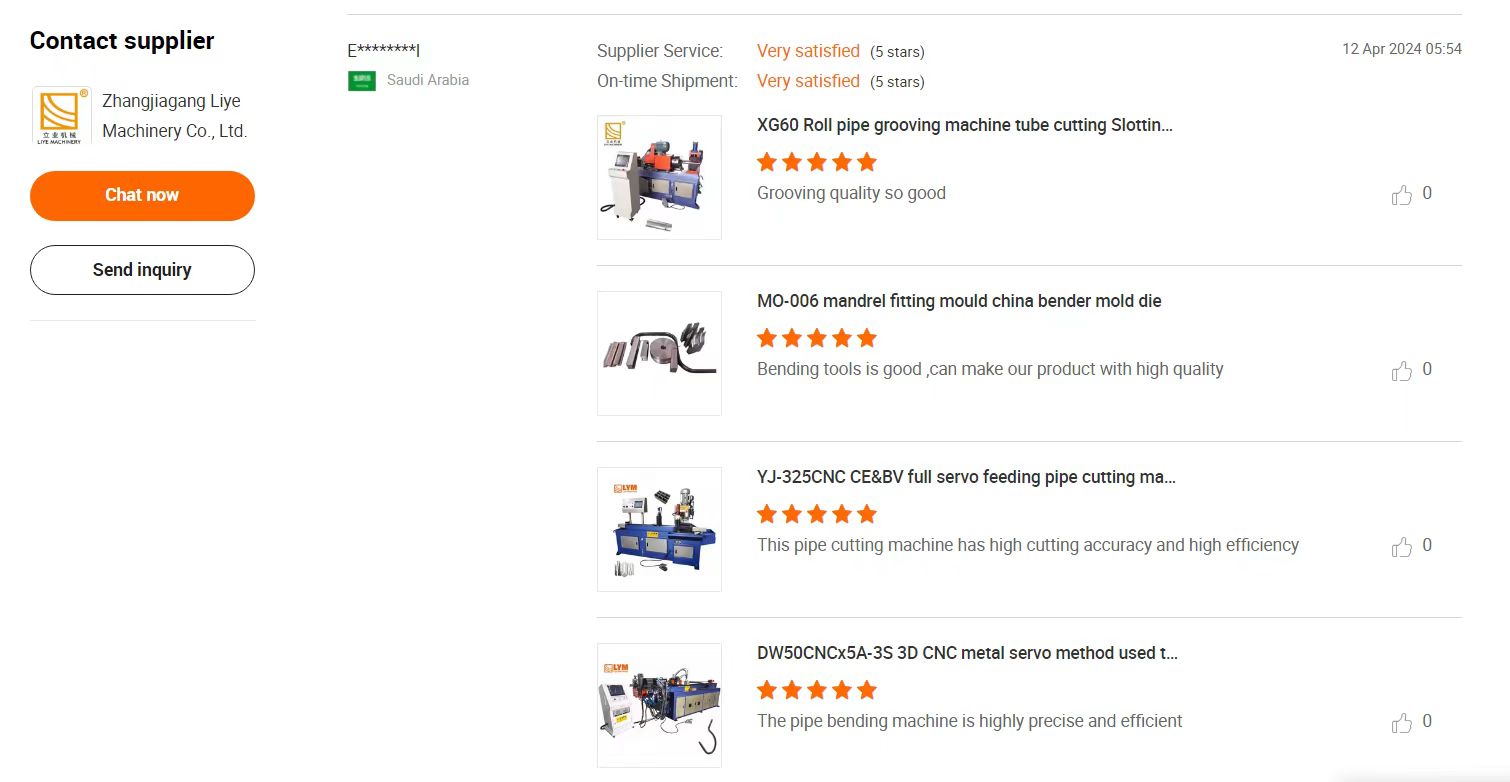

Customer Reviews