AUTOMATIC CNC TUBE BENDING MACHINE( LEFT AND RIGHT)

This CNC tube bender series features tube benders equipped with Left + Right Bending Technology for maximum flexibility and minimal interference, with a capacity up to OD 50.8 mm.- Direct supply from the manufacturer

- Order phone:+86-13812981723

- E-mail:liye@liyemachine.com

Detail

The new LYM CNC Left + Right Tube Bender combines Draw+Roll+Dual Direction Bending Way technology. This line is especially suitable for complex parts and shapes, such as automotive exhaust pipes, health care, and fitness equipment. It is equipped with multiple CNC axis.

Description

|

Brand Name: |

LYM |

|

Model Number: |

DW18CNCX3A/DW38CNC/DW50CNCX6A |

|

Type |

CNC CONTROL AUTOMATIC (LEFT AND RIGHT) |

|

Certification: |

CE/SGS/TUV/ISO |

|

Place of Origin: |

China |

|

Application |

Pipes or solid bars,various materials such as steel, stainless, aluminum and copper |

|

Packaging Details |

Packed in stretch film firstly,and then reinforced with plywood for outer packing |

• CNC multiple Servo Control Axis

• Easy Programming–Setup a part in the same way as a single directional bend

• Bending servo+Rotating servo+Feeding servo +Bend-head horizontal shift servo + Bend-head vertical shift servo

LYM's Tube Bender can be integrated with Automatic Loaders (AF, AFM, Robots) and Automatic Unloaders (AUL , ROBOTS) for full automation. This tube benders series can offer one of highest performance solutions available in the market.

LYM's unique technologyis the patented bending system that brings you the most efficient and stable bending process, offering the highest accuracy and repeatability in draw and roll bending.

• Self-diagnostics + Error messages display Auto compensation

• Bending interference and collision simulator

• Mirroring and image reversal of parts

PIPE BENDER MAIN TECHNICAL SPECIFICATION (CNC CONTOL / LEFT AND RIGHT BENDING)

|

Model |

Bending Capacity (mm) |

Max Bending Radius (mm) |

Axis |

Videos (Scan code) |

|

DW18CNCX3A |

OD 19.05 |

R80 |

3 |

|

|

DW38CNC |

OD 38.1 |

R180 |

3-6 |

|

|

DW50CNCX6A |

OD 50.8 |

R250 |

6 |

|

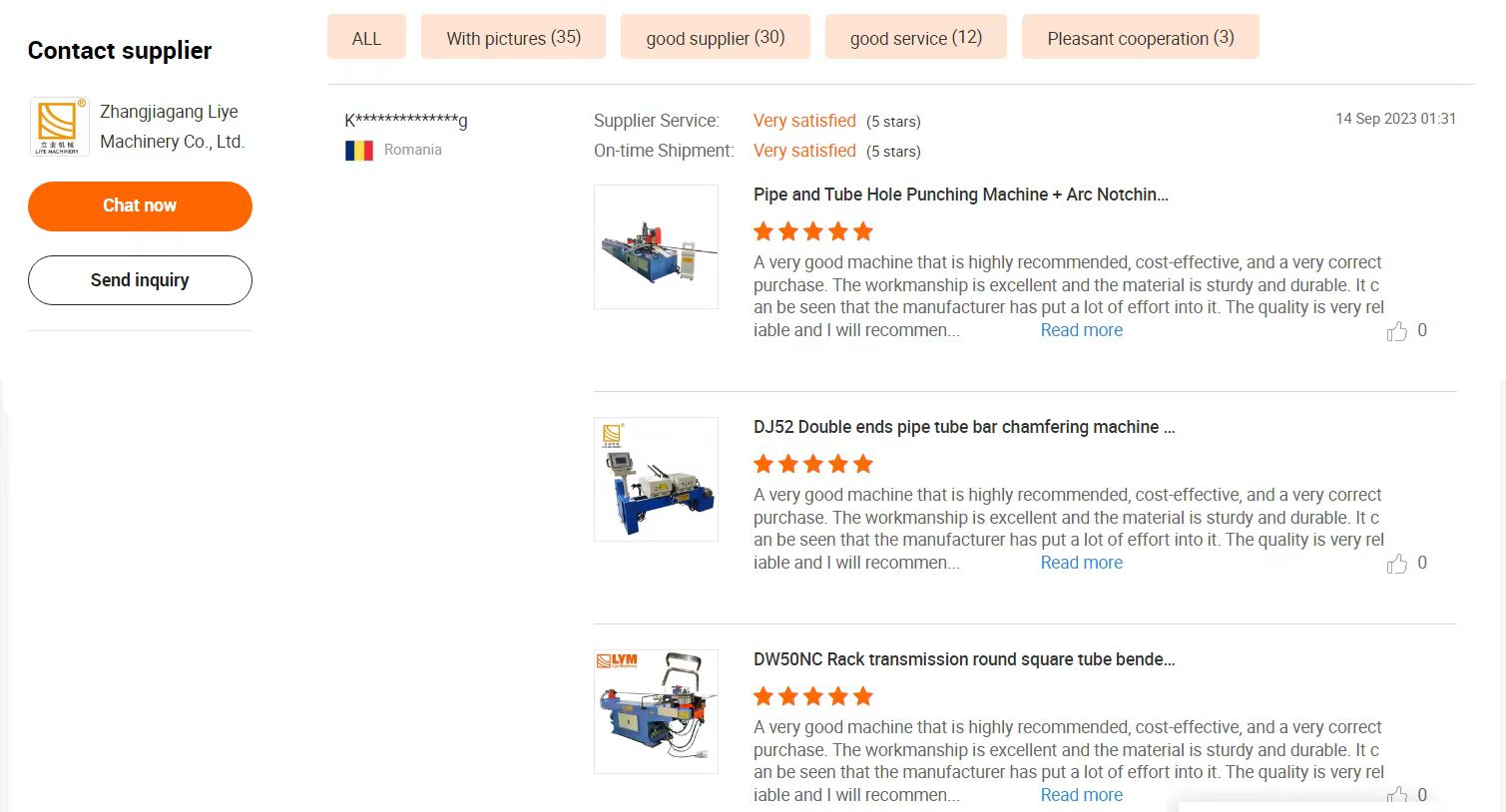

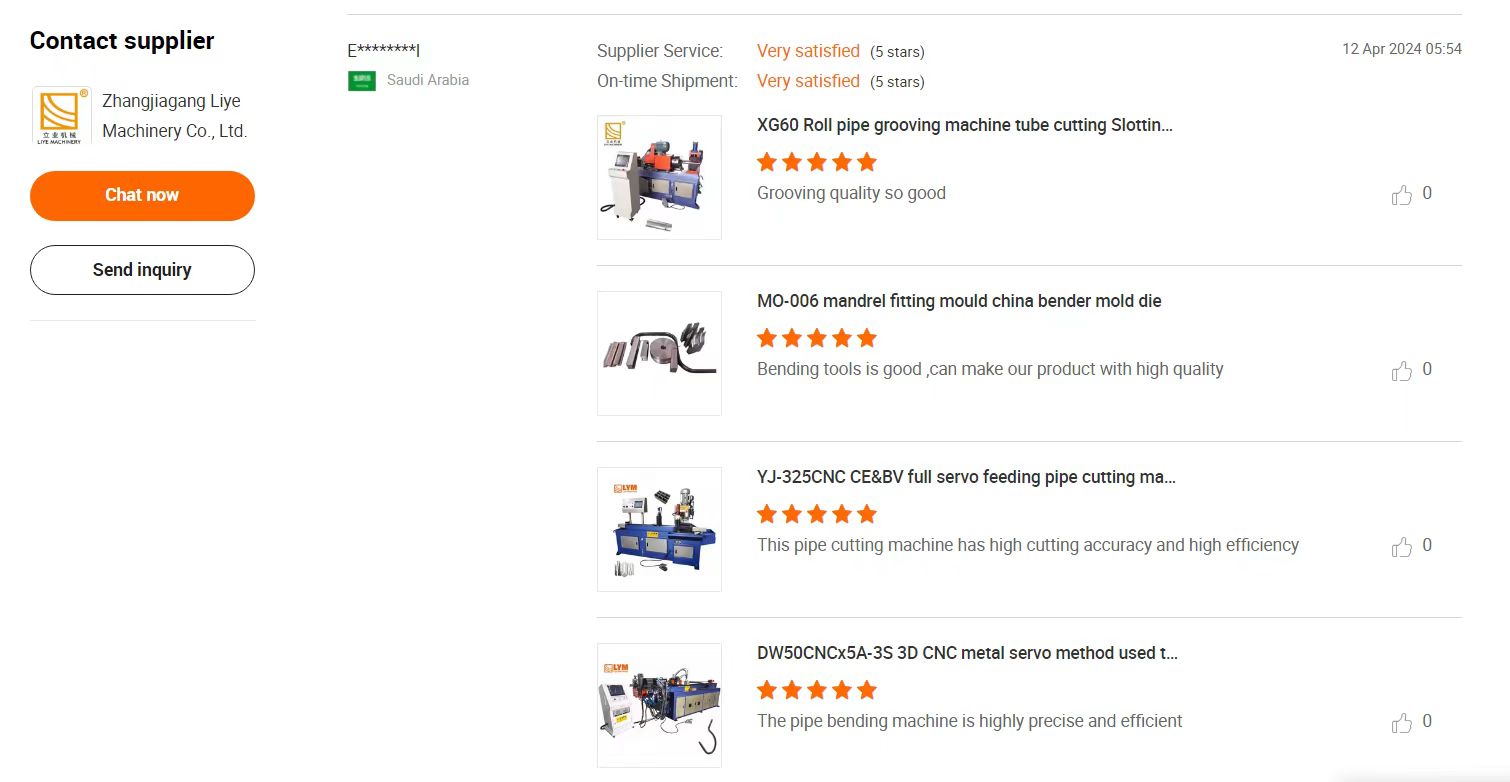

Customer Reviews